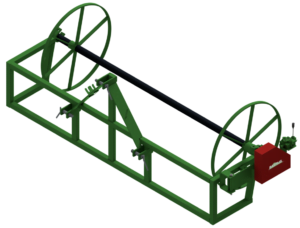

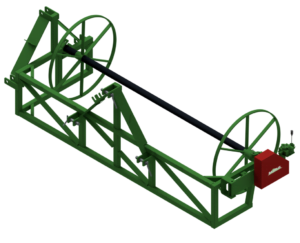

Foilwinder BPO

This film rewinder is suitable for rolling various types of film and fleececloth. Once rolled up with the machine, they are also easy to unroll again with the same machine.

Operating procedure

A roll-up tube is inserted into the machine. The film is tied around this tube. Operating the lever causes the roll-up tube to rotate and the film is rolled up. The 2 guide discs on the side ensure a straight roll. When the roll-up tube is full, the motor support can be turned away for easy removal of the roll of film.

General specifications

| Roll-up length per tube | 350 metres of film (at a width of 12 metres) |

| Roll width between guiding discs | 220 cm |

| Roll-up torque | 40 daNm |

Optional

- Guide arm

- Additional roll-up tubes

- Extra three-point on the side

- Additional guide discs

Common configurations

BPO\220

| Linkage | 3-Point linkage cat. 2 |

| Weight | 185 kg |

| Power requirement | 30 hp |

| Hydraulics | 1 (single) acting valve, 20 l/min |

BPO\220D

| Linkage | 3-Point linkage cat. 2 |

| Weight | 185 kg |

| Power requirement | 30 hp |

| Hydraulics | 1 (single) acting valve, 20 l/min |